OVERVIEW

The following case pack labeling guidelines are for the Nabis intake process of all inbound products that will adhere to Nabis’ Minimum Order Quantity (MOQ) distribution model.

ITEM CREATION

The brand will be required to input the following in the Nabis Portal. These inputs must remain constant per SKU. Any changes/adjustments to the pack/case quantities will require a new SKU to be created. All order creation will only allow for orders to be placed in Case Pack Quantities.

- Case Pack Quantity

- Master Case Quantity

-

Sample SKU

- All Trade samples must have a separate sample item set up, mirroring the full-priced SKU

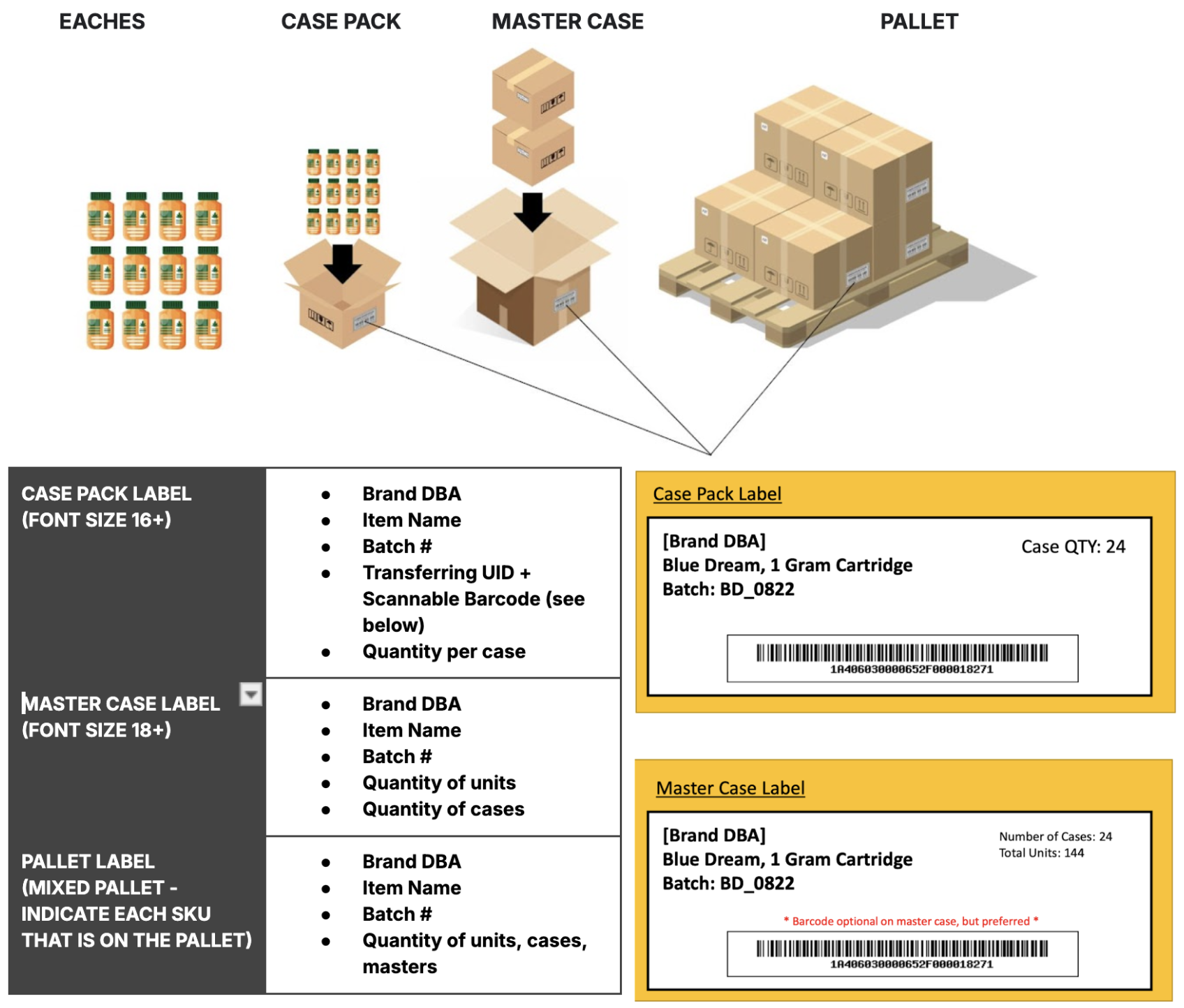

PACKAGING ILLUSTRATION

Failure to meet the above requirements for Case Pack and Master Case labeling will result in a delay in your intake.

LABELING

The chart above is a guideline for the required label information needed on each label location. All labels must be placed on the side-primary location for clear visibility with a minimum of 16pt font.

In order to meet the compliance requirement regarding DCC regulation 15048.5, case packs must include both the Metrc UID listed on the physical product, as well as the Metrc UID being sent to Nabis. (Code 128 Barcode only - this is a link to a free online tool you could use)

Note:

This UID + Scannable Barcode is required on ALL casepacks that come to Nabis. This is NOT the Source UID. Please reach out to help@nabis.com with any questions.

If we receive case-packs without the required information, we will apply the correct labels ourselves and apply our standard labeling fee to your next remittance.

DEFINITIONS, GUIDELINES, AND EXAMPLES OF THE ITEM CREATION INPUTS

EACHES OR INDIVIDUAL UNITS

All order quantities and inventory ledgers on Nabis represent individual unit quantities and are only able to be ordered by their respective SKU’s Case Pack quantities. For example, a SKU of pre-rolls packaged in Case Packs of 20 will only allow for order intervals of 20 (20, 40, 80, ... 200) in that order. This will eliminate the need to ‘casebreak’ in the distribution process and ensure that packages arrive at the retailer in the same state they left the manufacturer.

Nabis will no longer allow for the sale of individual units (with the exception of samples created on their own unique SKU, detailed below)

Nabis Receiving will only be received in Case Packs

Samples must be received in a Case Pack (you can use the same boxes/quantities) and then ordered against in individual units

CASE PACK

A Case Pack is the sealed container that individual units come in from the manufacturer in a set number of quantities per Case Pack and designated upon item creation in Nabis.

The Case Pack quantity is the interval of which orders will be placed for a respective product and so should reflect a viable Minimum Order Quantity (MOQ) that is desired. For example, if you expect to sell as little as 8 units consistently, a good Case Pack would be 8. If orders typically order 24, 48, or 96, a good Case Pack quantity would be 24

Case Pack quantity will be required upon item creation in Nabis, and products packed in totes or plastic bags are NOT considered case packs/master packs.

Case Packs remain sealed from manufacturer to retailer and are never opened by Nabis throughout the distribution process (receiving, shelving, picking, packing, and shipping) (with the exception of samples and routine verification upon receipt)

MASTER CASE

A Master Case is the sealed container that Case Packs come in from the manufacturer in a set number of quantities of Case Packs per SKU (popular quantities range from 4-32 inner packs per Master Case). For example, pre-rolls that are in Case Packs of 20 units and fits 10 Case Packs into their Master Case, the quantity of each Master Case is 200.

No master case should exceed 50 pounds. Anything heavier should be palletized.

The Master Case quantity is the interval by which wholesale orders are typically received and backstored. Master Case quantity will be specified upon item creation in Nabis.

PALLETS

All Master Cases are required to have total unit quantities on the label, along with total master packs that are on a pallet.

Pallets can be a maximum height of 6 feet (72 inches)

Full pallets are shrink-wrapped for the entire pallet

Mixed pallets have a visible space and dividers separating the different product cases

The brand must provide the total number of cases for a full pallet

SAMPLES "NOT FOR RESALE" ONLY

Samples Not-For-Resale (samples not sold to the end consumer but consumed by employees at the retailer) are individual units (eaches) designated as such and likewise distributed at odd intervals. Samples Not-For-Resale are required to be input as their own dedicated sample products & SKUs (the same batch will suffice for both your Parent & Sample SKUs) upon item creation. This allows them to be ordered as eaches or at odd intervals despite designated case quantities.

Samples must be received in case quantities, but can be ordered against as “eaches”

-

Trade Samples Not-For-Resale may not be pulled from non-sample SKUs

-

- Orders will designate samples and charge each item at 1¢ without excise tax, per CDTFA regs

-

All trade sample units must come labeled ‘Sample not for resale’

Discounts or promotions should be applied against the Parent Product using the Discount fields either in-line or off the subtotal of the order on the New Order Form

CASE SIZE DIMENSIONS

Upon product creation, Nabis requires accurate Length, Width, Height, and Weight of all case packs. This information informs everything from truck assignments to warehouse space reservations. This information is audited upon receipt, and we reserve the right to reject products that have inaccurate information.

HOW TO AVOID RELABELING SOP

As a distributor without a manufacturing license, Nabis is limited to relabeling potency, cannabinoids & terpenoids ONLY if the lab has determined that the products have been mislabeled yet fall within regulatory limits.

Typically, our brands pre-label with R&D test results so that the product arrives retail-ready and in its final form. When tested for Compliance, as long as results fall within a +/-10 % variance, there is no need to re-label. This gets your product to market faster so long as test results are consistent between R&D and Compliance. If it falls outside that range, it needs to be relabeled with the new %. We do not offer labeling services at this time and have limited visitors to inbound drop-offs only, so full batch relabel events must occur off-site.

§ 5303. Packaging and Labeling:

(a) A distributor may package, re-package, label, and re-label cannabis for retail sale.

(b) A distributor shall not package, re-package, label, or re-label manufactured cannabis products except when the distributor also holds a manufacturing license and is packaging, re-packaging, labeling, or re-labeling its own manufactured cannabis products.

(c) Notwithstanding subsection (b) of this section, if it is determined during laboratory testing that a manufactured product is labeled with the incorrect amount of THC per package or serving but is within the THC limits for sale, the distributor may re-label the package with the accurate THC amount. Distributors may also re-label the package with the accurate amount of cannabinoids and terpenoids if laboratory testing determines that the manufactured product is labeled with incorrect amounts.